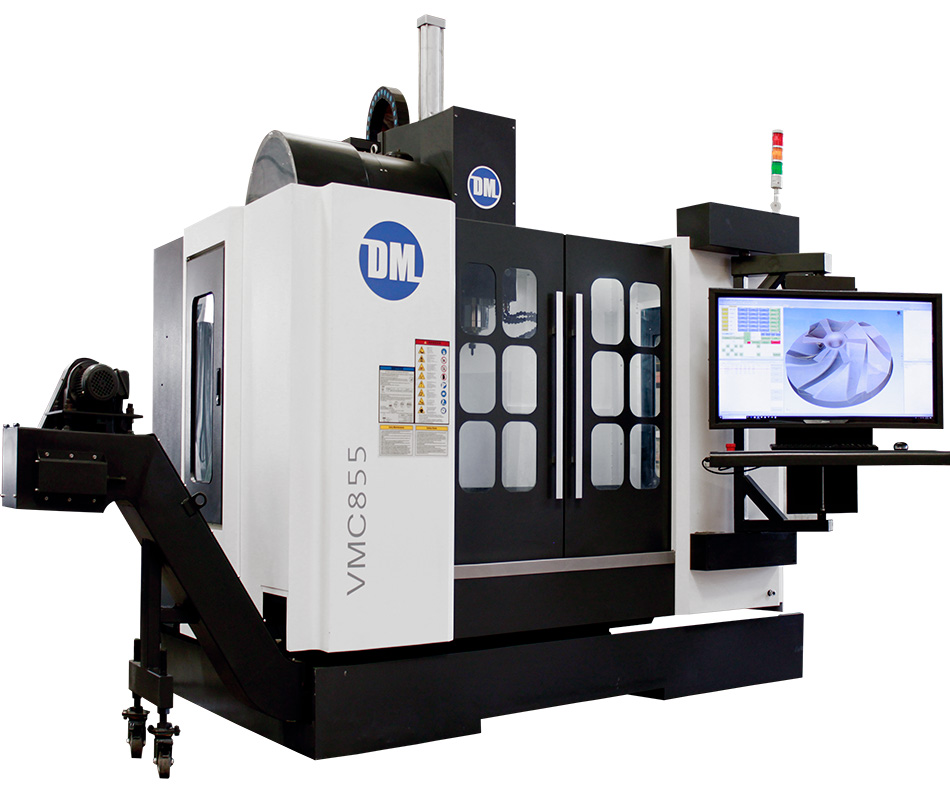

VMC855

Vertical Machining Center

Travels: 32" x 20" x 20"

3-5

AXIS24

TOOL ATC40

TAPER8K

SPINDLE RPMBase Price: $74,995

The DM Advantage is 4C

An end-to-end design & manufacturing solution

The DM VMC Series are high-performance vertical machining centers powered by 4C - our PC-based software and control system. 4C seamlessly integrates 3D CAD/CAM/CNC and CMM in one easy-to-learn package - with no outside software. 3D solid model part programming is done right on the machine’s 40" 4K touch display. From prototype to production manufacturing, DM's VMC Series with 4C has you covered.

Cut a part on day one, bring work in house

If you can run Win10, you can run 4C. No G-code experience is required, and minimal CAD/CAM experience is needed. You'll be able to cut a simple part on day one of training regardless of your CNC experience level. 4C increases workflow efficiency because one person can often replace a conventional CAM programmer and CNC operator.

Learn 4C 5x faster, maximize production

Since 4C runs on the machine, changes to toolpaths are done on the shop floor. You won’t be walking back and forth between the machine and a CAM workstation (like conventional systems). This means program changes are nearly instant, and leads to learning 4C 5x faster than other CAM programs. You’ll also fine-tune your programs in less time, so you can spend more time making chips.

Internet-based support, no finger pointing

When you buy a DM machine, you’re getting an end-to-end solution. DM supports the entire system (electronics/software/mechanical). You’ll have one point of contact for everything, and can video call or instant message directly from your machine. Internet-based support streamlines remote diagnostics and communication. We can even remotely operate your machine, as if we were right there with you.

Standard Equipment

- Software & Control: 4C CAD/CAM/CNC/CMM by Direct Motion

- Operating System: Windows 10

- Interface: 40" 4K Touch Display

- Fully Enclosed with Sliding Doors

- Tool Changer: Arm Automatic Tool Changer (ATC)

- Spindle: 8000 rpm, BT 40 Taper

- Linear Rails: XYZ axis

- Chip Removal: Chip Conveyor

- Coolant Tank

- Z Axis Pneumatic Counter Balance

- Cooling: A/C Unit for Control Cabinet

- Pendant: Remote Jog Handle

- PC Hardware: I5 Intel Processor, 8GB Ram, Solid State Drive (SSD), Mouse, Keyboard, Webcam, and Headset

- Warranty: 1-Year Standard Warranty

Machine Operations

|

|

Shop Requirements

- Wired high speed internet: 15Mb minimim speed required for remote support via Skype and Logmein

- Shop Ceiling: 12ft

- Shop Door: 10ft x 10ft

- Forklift: 20,000 lb capacity

- Electrical: 208-240V, 3Ph power with dedicated disconnect box and appropriate sized breaker (see machine specs). The disconnect box must be within 10ft of the right rear corner of the machine.

- Shop Air: 100 psi

Feature |

Benefit |

|---|---|

| Import or create 3D CAD solid models |

|

| Windows 10 PC based control | High performance, reliable platform at a low cost |

| Windows 10 desktop |

|

| Automatically create toolpaths from 3D models | No tedious line by line code |

| Quickly create toolpaths for individual features | Allows you to work and learn incrementally |

| Nearly instant toolpath changes | Fast programming with no more going back to CAM station and waiting |

| Fast learning curve | We guarantee you'll cut a simple part on day one of training regardless of your CNC experience level |

| Empowers the machinist at the machine | One person can often replace a CAM programmer and CNC operator, increasing workflow efficiency |

| Can handle complex valuable parts | Feature based on geometry, surfaces, intersections |

| Internet connected PC on the machine | The world is at your fingertips |

| Online training videos | Stream videos and run 4C on the same screen - on the machine |

| End-to-end system | CAD/CAM/CNC/CMM work together seamlessly |

| Single supplier for machine, electronics, software | You’ll have one point of contact for the entire system - no finger pointing |

| Internet-based support | Solve problems and get answers faster and easier by video calling or instant messaging from the machine |

| Remote diagnostics send data to DM servers | Our tech team can troubleshoot without visiting your shop |

| Remote automatic updates | Improvements and fixes are easy |

| Cloud program storage | Never lose a program |

| Import G-codes from outside CAM | Fits into G code workflow or 4C |

At The Machine Programming on 40" 4K Touch Display

Our built in 40" touch display is roughly the size of other conventional operator panels. Essentially we have replaced conventional fixed buttons with touch buttons (similar to smartphones). There are 10 different windows that an operator may want to interact with while using the machine, each of these windows can be docked in any location or floated. Multiple graphics screens can be shown simultaneously for different programs or subroutines. Camera(s) can also be mounted inside of the machine for an on screen video feed. The large screen fills up fast when you have this sort of information at your finger tips. Most operators find the standard mouse and keyboard more useful for programming parts, whereas operations such as jogging or changing tools are quicker on the touchscreen. The combination of the two input methods leads to a very productive machine.

Sit/Stand Operator Panel mounted on a Rotate & Swivel Arm

Our newly redesigned operator panel can be easily adjusted to the optimal height for operator comfort, while sitting or standing. It is also mounted on a rotate and swivel arm, allowing convenient positioning even partially inside the machine enclosure. Our CNC operator panel is the most convenient and ergonomic of any machining center available in today's market.

| Switch to Metric Units | S |

M |

L |

XL |

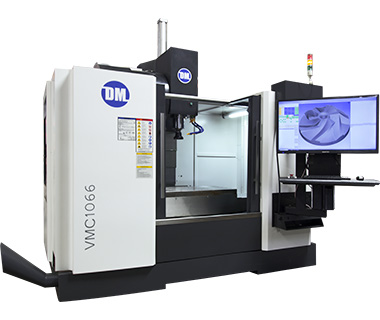

VMC644 |  VMC855 |  VMC1066 |  VMC1277 | |

| Starting At | $69,995 | $74,995 | $84,995 | $109,995 |

|---|---|---|---|---|

| Software & Control Unit | 4C by DM | 4C by DM | 4C by DM | 4C by DM |

| X Travel | 24" | 32" | 40" | 48" |

| Y Travel | 16" | 20" | 24" | 28" |

| Z Travel | 16" | 20" | 24" | 28" |

| Table Length | 32" | 39" | 47" | 47" |

| Table Width | 16" | 20" | 24" | 24" |

| Table Load Capacity | 1,323 lb | 1,764 lb | 2,094 lb | 2,094 lb |

| Machine Length | 94.5" | 88.5" | 104.3" | 114.0" |

| Machine Width | 94.5" | 86.5" | 94.5" | 98.5" |

| Machine Height | 94.5" | 108.3" | 123.3" | 128.0" |

| Machine Weight | 9,259 lb | 11,685 lb | 14,330 lb | 15,873 lb |

| Spindle Taper | BT 40 | BT 40 | BT 40 | BT 40 |

| Spindle Nose to table Min | 5.12" | 5.12" | 5.90" | 5.90" |

| Spindle Nose to Table Max | 20.87" | 26.77" | 29.53" | 33.45" |

| Spindle Power Continuous | 14.70 hp | 14.70 hp | 26.80 hp | 26.80 hp |

| Spindle Power (30 min rating) | 21.40 hp | 21.40 hp | 40.20 hp | 40.20 hp |

| Spindle Power Peak | 29.50 hp | 29.50 hp | 53.60 hp | 53.60 hp |

| Spindle Speed Standard | 8,000 rpm | 8,000 rpm | 8,000 rpm | 8,000 rpm |

| Spindle Speed Upgrade | 12,000 rpm | 12,000 rpm | 12,000 rpm | 12,000 rpm |

| Feed Rate | 600 ipm | 600 ipm | 600 ipm | 600 ipm |

| Rapid Rate | 1,000 ipm | 1,000 ipm | 1,000 ipm | 1,000 ipm |

| Repeatability | 0.0001" | 0.0001" | 0.0001" | 0.0001" |

| Accuracy | 0.0002" / 12" | 0.0002" / 12" | 0.0002" / 12" | 0.0002" / 12" |

| ATC Number of Tools | 16 | 24 | 24 | 24 |

| ATC Tool Change Time t-t | 1.5 seconds | 1.5 seconds | 1.5 seconds | 1.5 seconds |

| ATC Tool Change Time c-c | 5.0 seconds | 5.0 seconds | 5.0 seconds | 5.0 seconds |

| ATC Max Tool Length | 11.81" | 11.81" | 11.81" | 11.81" |

| ATC Max Tool Diameter (full) | 3.15" | 3.15" | 3.15" | 3.15" |

| ATC Max Tool Diameter (no adjacent tools) | 5.10" | 5.10" | 5.10" | 5.10" |

| ATC Max Tool Weight | 18 lb | 18 lb | 18 lb | 18 lb |

| Wall Circuit breaker requirement (If electrical service is less than specified values, then spindle peak power can be lowered to match) |

75 amps | 75 amps | 125 amps | 125 amps |